Photolithography

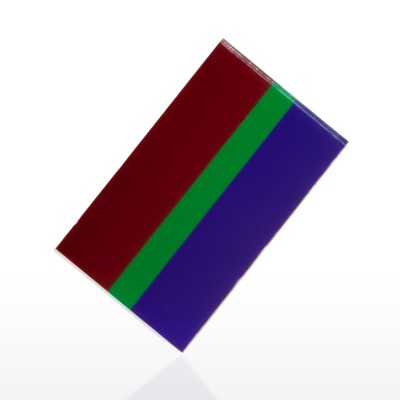

Reynard Corporation offers custom patterned thin film optical coatings to produce a wide range of complex optics with geometries on substrates up to 18 inches in diameter using our highly accurate photolithography process.

Reynard Corporation offers custom patterned thin film optical coatings to produce a wide range of complex optics with geometries on substrates up to 18 inches in diameter using our highly accurate photolithography process.

A thin film patterned optic can be applied to any vacuum compatible optical substrate material, including optical glass, certain plastics, and ceramics to produce a variety of shapes to meet your custom optical coating requirements.

• Pattern Geometries Down to 5µm

• Multiple Pattern Stacking

• Gapless Patterns – no physical space between adjacent coatings

• Custom Patterns

• Front Surface to Back Surface Pattern Alignment to ≤ 25mm

All optical elements are thin film designed, manufactured, and tested in-house.

ISO 9001:2015 certified and ITAR registered.

Contact us for a custom quote!

CAPABILITIES

- UV curable / dissolvable polymeric photoresist

- Front to back surface patterned alignment to ≤ 25µm

- 5µm and above geometry resolution

- Multiple pattern stacking, alignment tolerance 25µm and above

- Optical coating thickness up to 7µm

- Photoresist thicknesses up to 100µm

- Dielectric and metal coatings

- As large as 18″ in diameter

- Multi-Spectral Detector Filters

SUBSTRATE MATERIAL

- Glass

- Plastics (certain types)

- Ceramics

- Metal

APPLICATIONS

- Alignment Test & Reference Patterns

- Heated Windows

- Scope Crosshairs

- Filters: Patterned & Comparison

- Beamsplitters: Polka Dot & Wideband

- Boresights

- Scopes Reticles

- Fluorescence Imaging

- Barcodes

- Pinholes and Optical Slits

- Patterns: Resolution & QC

- Alignment Test Patterns

- Devices: Non-Imaging

- Angle Measuring

- Encoder Disks

- Environmental Sensors

- Multi-Spectral Detector Filters

- Machine Vision

- Automated Inspection

- Targets: Optical & Military

- Imaging & Color Calibration

- Hyperspectral