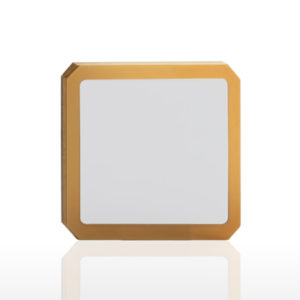

High optical transmission with matched impedance

Reynard, a principal global supplier of custom optics and thin film coatings, creates custom optical heated windows utilizing conductive materials. Heated windows are the most resourceful way of keeping imaging planes or optical instrumentation windows free of moisture or fog.

Reynard’s heated window patterns are customizable to achieve high transmission and/or matched impedance to meet the exacting requirements of your system.

Our optical heated window patterns can be customized in design to achieve high transmission and/or matched impedance to meet the requirements of most any system. The substrate size, shape, and type can also be customized to meet the necessary requirements. Bus bars added to the edge of the optics provide solder points for electrical leads. Adding an anti-reflection coating to one or two sides of the optic provides enhanced transmission while providing an extra layer of protection to the conductive surface.

Several types of heated windows are available:

Solid ITO: Provides a highly transparent and conductive film over the surface of the optic for visible and NIR wavelengths. The controlled thickness of the applied ITO controls the impedance.

Lines: Bus bar to bus bar lines typically required to be matched in length, for controlled impedance. These lines can be applied from either ITO or highly conductive metals, such as gold.

Grids: Grid patterns provide a balance between impedance control, high transmission, and robustness. Grid patterns are typically used when the optic is in environments where the gird surface can be scratched, yet impedance control needs to be maintained. Patterns can be applied from either ITO or highly conductive metals.

Key features include:

- Customized or standard patterns, down to 10um line widths

- Use of highly conductive materials, such as ITO or gold

- High transmission in desired wavelength spectrum, from visible to far IR

- Application to most substrates, including thick optics, plastics, and flexible membranes

“Without a heated window, condensation buildup in the viewing window of an imaging system could deem the entire system ineffective”, says Forrest Reynard, CEO of Reynard. “Systems that quickly traverse from cold to warm environmental conditions see condensation buildup due to slow thermal mass changes in the system compared to the external environment. Heating the imaging window so that it thermally matches external environmental conditions eliminates condensation buildup.”

About Reynard

Established in 1984, Reynard manufactures custom precision optics & thin film coatings 0.2 µm to 15 µm (UV-IR) to demanding specs for military, commercial, industrial and medical applications. Their expertise in these markets enables them to provide advanced optical solutions while building strong reliable relationships with customers. Other in-house services include optical fabrication, diamond turning, photolithography patterns & environmental testing. Prototype to production, ISO 9001:2015 Certified, ITAR Registered and CMMC Cybersecurity Compliant. Reynard looks forward to working with you in Perfecting Your Light ™.

For more information, please visit: http://www.reynardcorp.com or contact us at (949) 366-8866 & sales@reynardcorp.com