Performance Enhancing

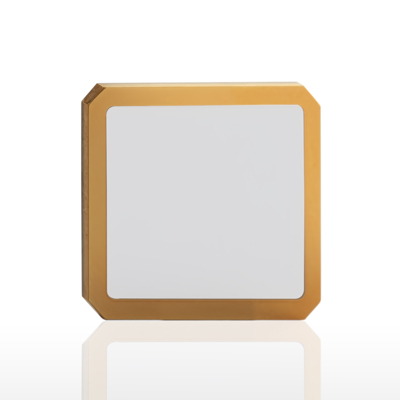

Reynard Corporation produces a wide variety of metallic mirror coatings including aluminum, gold and silver providing a moderate level of reflection over an extremely broad spectral range. Most metals can be evaporated including gold, aluminum, silver, copper, nickel and many more, tend to be soft and need a dielectric coating for protection. Metallic mirror coatings have a broader reflection bandwidth compared to dielectric mirrors.

Reynard Corporation produces a wide variety of metallic mirror coatings including aluminum, gold and silver providing a moderate level of reflection over an extremely broad spectral range. Most metals can be evaporated including gold, aluminum, silver, copper, nickel and many more, tend to be soft and need a dielectric coating for protection. Metallic mirror coatings have a broader reflection bandwidth compared to dielectric mirrors.

We can supply a variety of custom metallic mirror coatings for your specific application!

• Busbar Connections

• EMI Shielding

• Solder Pads/ Hermetic Seals / Solder Sealing / Metal Grids

• Edge and Surface Coating Capabilities

• Durable: 30 Minute Boiling Water

• Tensile Pull Strength to ≥ 10,000 psi

Custom prototypes to volume production are available.

Contact us with your custom optical coating requirements!

SPECIFICATIONS:

| Metallic Coating Types: | Aluminum: Bare, Protected, Enhanced, UV Protected, UV Enhanced Black: Opaque Gold: Bare Gold & Protected Gold Silver: Protected First Surface Silver & Protected Second Surface Silver |

| Sizes: | 25mm to 200mm |

| Coating Materials: | Aluminum, Gold, Silver, Nickel, Inconel, Chrome |

| Substrate Materials: | Glass, Ceramic, Metal, and Plastic |

APPLICATIONS

- Lighting Systems

- Laser Systems

- Illumination Systems

- Digital Imaging

- Bus Bars

- Metal Grids

- EMI Shielding

- Optical Sensors

- Hermetic Seals

- Telescope Mirrors

- Bar Scanners

- IR Imaging Systems

- Surveillance

- Solder Pads

- Mirrors

- Laser Scanners