A unique way of monitoring corrosive environments

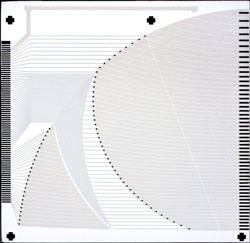

Reynard, a leading global supplier of custom optics and thin film coatings announces thin film-based environmental gauges. Thin film-based environmental gauges are manufactured by depositing environmentally susceptible coating materials onto an inert substrate. Coating materials are typically deposited in a custom defined quasi-grid pattern of lines. Redundant traces, matched in length and size, can be implemented to monitor environmental changes over a small region, such as for rising gas or fluid conditions, or to provide damage protection when used in abrasive conditions.

Unmatched lines allow for the variable open-space monitoring of increasing corrosion levels, or for the monitoring of different types of corrosive elements. Grid configurations are designed for specific operational environments and can utilize a combination of matched and unmatched lines to achieve the required electrical characteristics.

The detection of environmental caused degradation is accomplished by monitoring the change in electrical characteristics from one side, or zone, of the environmental gauge to another. Photolithography techniques are utilized to achieve repeatable, high-precision transmission characteristics in confined areas to meet your system requirements.

“Environmental gauges are a unique way of monitoring corrosive environments” says Forrest Reynard, CEO of Reynard.

Materials such as Copper, Silver, Aluminum, Iron, and Zinc are commonly used for these lines, although other materials, or dopants, required for specific applications can also be deposited. Traces can be added to most any substrate type, even to flexible substrates such as Melinex®.

Reynard Corporation’s thin film engineers will work closely with you to ensure product key characteristics are properly defined and the highest reliability product is delivered on-time to meet the demands of your custom application.

Key Characteristics:

- Custom grid line configurations

- Photolithography based precision and repeatability

- Materials to match your application

About Reynard

Established in 1984, Reynard manufactures custom precision optics & thin film coatings 0.2 µm to 15 µm (UV-IR) to demanding specs for military, commercial, industrial and medical applications. Their expertise in these markets enables them to provide advanced optical solutions while building strong reliable relationships with customers. Other in-house services include optical & mechanical fabrication, diamond turning, photolithography patterns & environmental testing. Prototype to production, ISO 9001:2015 Certified, ITAR Registered and CMMC Cybersecurity Compliant. Reynard looks forward to working with you in Perfecting Your Light ™.

For more information, please visit: http://www.reynardcorp.com or contact us at (949) 366-8866 & sales@reynardcorp.com