Balances undesirable intensity variations in optical systems

Reynard, a worldwide supplier of custom optics and thin film coatings, announces the Bullseye® apodizing neutral density optical filter. This optical filter is part of the Bullseye® apodizer line of customizable optical gradient filters and eradicate undesirable intensity variations in optical systems.

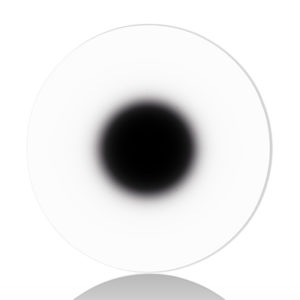

The density of the optical filter decreases radially from a dark center, where light is usually at its peak intensity, to the outside edge, where it can become completely transparent.

The density of the optical filter decreases radially from a dark center, where light is usually at its peak intensity, to the outside edge, where it can become completely transparent.

“…a Bullseye® ND optical filter can be used to solve basic light distribution problems, saving both time and money,” says Forrest Reynard, CEO of Reynard.

The Bullseye® apodizing optical filter can be designed for any Gaussian function regardless to the size of the beam. The optical filters are produced on a custom basis, as uniformity variations, substrate type, and bandwidth are a function of the customer’s specific optical requirement.

Key features include:

- Density gradients can be customized to suit any application

- The optical filter can be applied to a number of different substrate types

- Can be designed to be used from UV to IR.

Inserting a Bullseye® apodizing optical filter at the aperture stop of your imaging system modifies the intensity variations of your light source which can result in a flat top distribution.

“Instead of spending effort searching for ideal light sources for your specific application, a Bullseye® ND optical filter can be used to solve basic light distribution problems, saving both time and money” says Forrest Reynard, CEO of Reynard Corporation.

Application examples are found in diverse industries, such as:

- Entertainment – Make light distribution uneven for cosmetic applications.

- Imaging – Break up diffraction patterns by the introduction of soft edges.

- Industrial – Control the light emission from an automatic welding torch to a CCD camera. The filter is used in series with an iris in camera to eliminate detector saturation so that the welding operation can be viewed real time.

- Military – Eliminate IR detector saturation in ground-to-air and air-to-air missiles.

- Scientific – Used as a variable phase plate when the gradient coating material has the same index of refraction as the substrate.

- Semiconductor – Used in photolithography exposing systems to obtain perfect illumination distribution.

About Reynard

Established in 1984, Reynard manufactures custom precision optics & thin film coatings 0.2 µm to 15 µm (UV-IR) to demanding specs for military, commercial, industrial and medical applications. Their expertise in these markets enables them to provide advanced optical solutions while building strong reliable relationships with customers. Other in-house services include optical fabrication, diamond turning, photolithography patterns & environmental testing. Prototype to production, ISO 9001:2015 Certified, ITAR Registered and CMMC Cybersecurity Compliant. Reynard looks forward to working with you in Perfecting Your Light ™.

For more information, please visit: https://www.reynardcorp.com or contact us at (949) 366-8866 & sales@reynardcorp.com